Dark Ages Re-Creation Company

Dark Ages Re-Creation Company

Note: I get a number of requests each week via e-mail about various objects from the Viking Age. A good number relate to knives. To avoid me repeating myself, I have put together this piece, which may prove the starting point for a more comprehensive survey in the future...

In preparing this essay I have relied heavily on :

'Anglo-Scandinavian Ironwork from Coppergate' by Patrick Ottaway (York Archaeological Trust, 1992)

Many observations were drawn from my own personal studies of the material culture

of the Viking Age, plus work I have done on a number of major museum exhibits.

Add to this over 25 years practical experience as a blacksmith specializing

in historic forms and techniques.

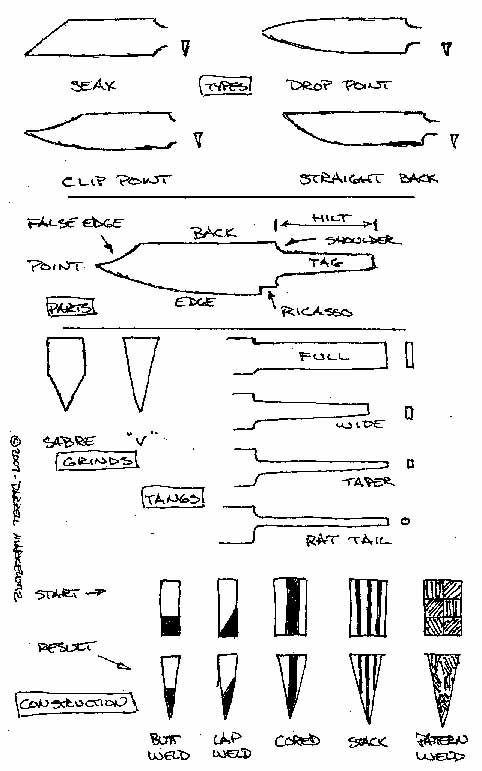

There appears to be no standard nomenclature for describing all the various features related to knives. The illustrations below will diagram the terms that I will be using relating to blade profiles and construction methods.

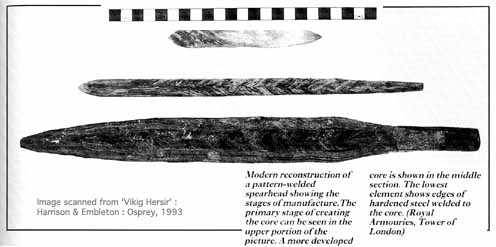

The term 'pattern welding' is used here in its archaeological definition (rather than as the term is incorrectly used by many contemporary knife makers). The method appears to have been invented in Europe some time around 100 - 200 AD. The first blades showing the technique are often found in a Roman military context. At its simplest form, pattern welded blades start as a pile of stacked plates of iron metals of varying carbon content. It is common to see starting stacks of 7 or 9 layers, this number not due to any mystical purpose. The simple reason is that the physical size of the stack lends itself to effective heating and hammering. The plates are secured together and forge welded into a solid block. This block is then drawn to a long rod and twisted. Several such rods are then welded together to form the body of the billet from which the blade is forged. By alternating direction of the twists, or twisted and straight sections, highly decorative patterns can be produced. The set of V shaped lines generating a herring bone effect is most distinctive of the technique.

The problem that the serious re-enactor has when considering the knives used during the Viking Age often comes down to a simple one of lack source material. In most popular overviews of Norse physical culture, knives may be at best covered by a few lines and perhaps an image or two of an artifact. Even in the more academic publications, there are few that deal with iron objects in detail, much less knives specifically. (An exception would be 'Knives and Scabbards' from the excellent 'Medieval Finds from Excavations in London' series. Unfortunately, the earliest blade detailed in that volume is from the early 1100's.) Generally, most archaeological sites are unlikely to yield more than a handful of knives, so finding detailed descriptions means digging through a large pile of often hard to access reports. One exception to this are large scale excavations of Viking Age town sites which have been undertaken in the last several decades. The Coppergate site at York, England has yielded over 200 knives, Helgo at Sweden a similar number, and Woods Quay at Dublin Ireland is reported to have produced over 400. This report is primarily based on the Coopergate materials, as I have not been able to acquire a detailed report for the Helgo excavations, and the Woods Quay materials are sadly yet to be published.

Looking over grave finds from across the Norse world during the Viking Age,

one fact does become obvious. Knives were considered essential tools, and appear

to be carried by everyone. There is no limitation on this use, either by sex

or age. This also seems to apply to the entire spread of both time and geography.

There is a slight tendency for the heavier seax style blade to be found in male

burials, most especially when it comes to the longer combat variations. This

is not a clear cut division however, and may have somewhat to do with the flexibility

in women's roles in Norse society.

Most knives in the Viking Age will taper in thickness slightly as they run from the hilt to the point. This feature is most likely a result of the smith wanting to stretch the metal to get as much length as possible. It also tends to effect the handling of the finished knife. The greatest weight of the blade is placed closest to the handle, making the tip feel light and increasing control. This does tend to reduce the relative impact force that can be delivered towards the working end of the blade. Generally there is little hard data recorded (even in primary reports) on the degree of taper on any individual object, other than noting the shape in general.

The first overall consideration when looking at knives from the Viking Age is shape and size. Generally we can break the blade shapes into two main groups, the classic 'small tool' and the distinctive 'seax'.

The small tool blade shape is one of the most ancient. It can trace its development back at least to the first use of copper (copper) cutting edges, perhaps even back to the neolithic period. At its simplest, the small tool is a long thin triangle with one edge sharpened. The point may lift above or drop below the mid line of the blade. Generally both the back and edge will be relatively straight, with some amount of curvature to either surface towards the point. Generally the blade is considerably long in proportion to its width. In the collection from Coppergate, knives of this profile make up 55% (98) of the total number.

The 'seax' is a specialized variation of the more generic 'clip point' style. In the seax, the edge is basically straight. The back will make a dramatic diagonal slope down from its widest point towards this edge to create the point. The word 'Seax' means 'knife' in the tongue of the tribe who came to be known for their distinctive knives - the Saxons. The seax shape has a number of variations, but also was a popular blade shape for the Norse. The profile creates a sturdier and heavier blade, well suited to tasks like splitting kindling.

There are three basic modifications to the overall layout:

Seax blades from the Viking Age almost always have either parallel sides or taper upwards to the cut. In some cases the diagonal cut is a shallow concave arc. One reason to produce a blade with its greatest width just at the start of the downwards cut is to increase the impact energy delivered by a downwards hacking stroke. This feature is most desired in heavy tool or certain styles of combat knives.

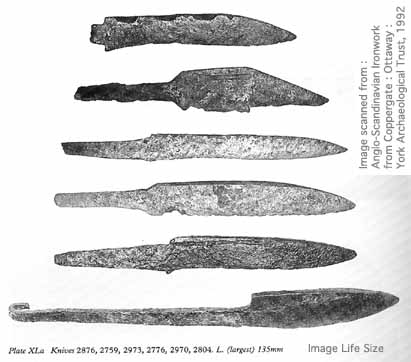

When taking a look across the entire collection of 200 plus knives found at Coppergate, The first thing that strikes you is the relatively small size of the individual blades. Of course certain care must be taken before applying measurements from this sample to the wider Norse Culture. Perhaps most importantly, the objects found at Coppergate can be considered to represent 'lost' items. It is unlikely any of these items were intentionally deposited, as is the case with blades found in graves for example. Smaller items are certainly more likely to be lost than larger ones, both due to size alone and the effort likely to be expended in finding bigger, and thus more valuable, pieces. Despite this, the fact that there is such a large number of objects found certainly suggests they existed commonly enough that many could have been available to be misplaced.

'Anglo-Scandinavian Ironwork' charts out the individual knives in graphs that describe a number of physical characteristics. There are definite spikes when grouping the found knives by blade length and width:

A table style comparison of was prepared listing details of 28 of the knives found at 16 - 22 Coppergate. To prepare the table, measurements were taken from the scaled drawings, descriptions and other date presented in 'Anglo Scandinavian Ironwork from Coppergate'.

| PAGE | NUMBER | DATE | TYPE | DETAIL 2 | LENGTH | BLADE | WIDTH | THICK | GRIND | MATERIAL | DETAIL 3 | TANG | HANDLE | NOTES |

| 560 | 2756 | 850 - 900 | seax | long diagonal | 23 | 13 | 3 | 0.6 | V | pattern weld | flat taper | |||

| 560 | 2761 | 850 - 900 | seax | long diagonal | 6.5 | 1.8 | 0.4 | V | flat taper | bevel at back | ||||

| 560 | 2763 | 850 - 900 | seax | long diagonal | 8 | 1.6 | 0.4 | V | flat taper | grooved | ||||

| 560 | 2764 | 850 - 900 | seax | long diagonal | 8.5 | 1.6 | 0.4 | V | flat taper | grooved | ||||

| 560 | 2767 | 850 - 900 | drop point | edge straight | 8 | 1.2 | 0.5 | V | butt weld edge | thin strip | wide flat taper | |||

| 560 | 2772 | 850 - 900 | drop point | edge straight | 8 | 1.4 | 0.3 | V | wide flat taper | 3 x grooves | ||||

| 561 | 2773 | 850 - 900 | drop point | edge straight | 7 | 1.4 | 0.3 | V | wide flat taper | |||||

| 561 | 2776 | 850 - 900 | drop point | midline point | 7 | 1 | 0.3 | V | wide flat taper | bevel at back | ||||

| 561 | 2783 | 850 - 900 | drop point | midline point | 6.5 | 1.6 | 0.4 | V | wide flat taper | |||||

| 562 | 2798 | c 930 - 935 | seax | taper up to clip | 11 | 6.5 | 2.2 | 0.3 | V | piled back | 4 x same metal | wide flat taper | 1.8 cm at hilt | |

| 562 | 2799 | c 930 - 935 | seax | taper up to clip | 20.5 | 10 | 2.2 | 0.4 | V | flat taper | 2 at hilt, curved lines on back | |||

| 562 | 2800 | c 930 - 935 | clip point | point above midline | 14 | 9 | 1.2 | 0.4 | V | carbon varies | hardest to edge | flat taper | curved false edge | |

| 562 | 2801 | c 930 - 935 | drop point | midline point | 13 | 9 | 1.6 | 0.5 | V | steel core | iron slab sides | straight rectangle | wide fuller | |

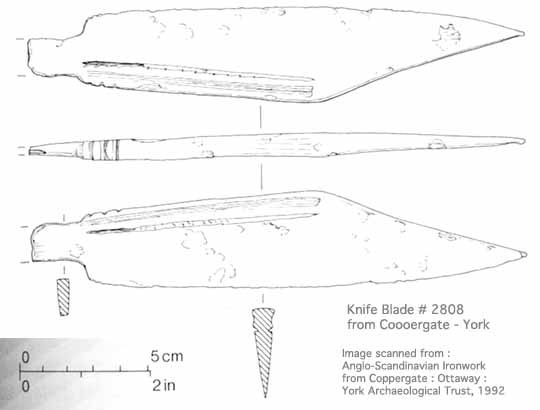

| 563 | 2808 | c 930 - 975 | seax | slight lift to point | 15 | 3.3 | 0.8 | V | steel core | iron slab sides | fuller + groove, curved false edge | |||

| 566 | 2810 | c 930 - 975 | straight back | slight drop to point | 10 | 2 | 0.3 | Y | wide flat taper | long curve to edge | ||||

| 566 | 2811 | c 930 - 975 | clip point | point above midline | 19 | 3.3 | 0.4 | sabre | flat taper | curved false edge, taper up to clip | ||||

| 566 | 2812 | c 930 - 975 | drop point | point above midline | 19 | 8.5 | 1.6 | 0.3 | V | flat taper | oval | long curve to edge, handle carved | ||

| 566 | 2826 | c 930 - 975 | straight back | slight drop to point | 15 | 1.8 | 0.3 | V | straight rectangle | long curve to edge | ||||

| 567 | 2833 | c 930 - 975 | straight back | slight drop to point | 16 | 8 | 1.3 | 0.4 | sabre | square, slight taper | cylinder sections | |||

| 567 | 2837 | c 930 - 975 | drop point | midline point | 14 | 7.5 | 1.4 | 0.4 | sabre | thickest before point | ||||

| 568 | 2860 | c 930 - 975 | drop point | midline point | 15 | 7 | 1.8 | 0.4 | V | inset steel | 2 + V insert | ofset to edge, taper | fuller, both sides long curve | |

| 569 | 2876 | c 975 | seax | curved back | 6 | 1.2 | 0.6 | V | knotches cut along back | |||||

| 569 | 2892 | c 975 | seax | taper up to clip | 12.5 | 1.1 | 0.5 | V | pattern weld | 3 + 3 on core | long diagonal to clip | |||

| 569 | 2895 | c 975 | seax | taper up to clip | 8 | 2.2 | 0.3 | V | curves up to midline | |||||

| 569 | 2907 | c 975 | straight back | slight drop to point | 19 | 10.5 | 1.6 | 0.4 | sabre | wide flat taper | ||||

| 569 | 2909 | c 975 | drop point | point above midline | 16.5 | 8 | 1.8 | 0.4 | V | flat taper | tear drop | tang buried in handle (no peen) |

Samples were chosen to represent the primary types found. Total length is given for only those knives that retained their full tangs. Although a number of blades were sampled for metallographical analysis, in most cases these tended to be the more fragmentary objects. For that reason construction details were only available for less than half the objects selected for the table. Some care has to be taken when applying measurements from the artifacts to modern reconstructions, as almost all the blades found at Coppergate show considerable wear - the results of full and useful lives.

Regardless of the actual profile of the blade, Most knives in the Viking Age have a fairly pronounced V shaped cross sections. They tend to be fairly robust in the maximum thickness at the back of the blade as well, especially when considered in terms of the width of the blades as discussed above.

There is considerable variation on the material that composes the blades themselves. As might be expected there is a wide range of both raw materials and techniques represented. Many of the samples at Coppergate appear to have had a harder higher carbon 'steel' applied for the cutting edges and softer low carbon iron for the backs, at least originally. (Those blades with extensive wear often showed little or none of the steel layer remaining as the result of endless sharpening) The collection shows a range of methods of welding together these different materials, ranging from simple butt welding, inset edge, through layered stacks to five knives that show distinctive pattern welding. Generally some kind of butt welded or inset harder steel cutting edge on to a soft iron body is the most commonly seen construction method.

Viking Age knives almost always have narrow tangs - often narrower than would be considered standard for a modern bladesmith. Generally these are rectangular in cross section, and almost always have a considerably narrow width compared to that of the blade. They also will taper sharply along their length towards the tip, generally extending the entire length of the handle. The shoulders between tang and blade are generally rounded, indicating they were forged into shape. Rarely do tangs show any holes indicating rivets were used. In those knives with complete tangs remaining, the ends of the tangs are either folded over or mushed indicating peening.

Handles when found are almost always solid tubes, or in some cases a series of barrel shapes. The standard method of attaching the handle was to drill or burn a hole down the centre of a block of wood, antler or bone and insert the tang through this hole. The blade end of the hilt material would be carved out to accept the shoulders, so the handle would fit up snug to the full width of the blade. In some cases a metal disk was then used to cap the handle material (much like a washer). Regardless of the use of a top cap, the end of the tang was then hammered to spread it, thus holding the handle in place.

Handles are often found carved, with a range of skill exhibited by the artisan who undertook the work. This may range from simple inscribed lines to full relief carvings of knotwork or animals. The handle material may also be reinforced by the use of wrapped wire or metal bands formed from soldered sheet.

Knives almost without exception do not possess any kind of guards. The first reason for this is a purely technical one, based on the construction method discussed above. The rounded shoulders most typical of all Norse knives would make fitting any kind of guard tightly extremely difficult.

Scabbards are most commonly of the pouch variety, which again is a reflection of the construction techniques used. These pouches usually cover almost all the hilt, so that only a small amount of the handle material protrudes from the leather case. This makes for a very secure holding method, but does mean that drawing the blade is fairly difficult. Knives most often hang from an upper loop or slot and so at right angles to the belt. In graves these are often found positioned on the left side of the body. In some cases smaller knives are found in woman's graves such that they must have hung from the broaches or been attached to the bead festoon. (The size of the blade and the location both suggest use as textile tools.)

Some pouch scabbards are reinforced with a metal strip down one side. Most commonly any metal mounts on scabbards are made from bronze. Scabbards for larger knives will often have two support loops through this strip. These are commonly found positioned on the skeleton laid flat across the stomach, hanging with the hilt to the right.

Iron knife with silver wire in the area between the handle and

the blade.

From a female grave (grave 503 at Ihre, Hellvi parish, Gotland). 9-10th C.

Viking Age knife from Gotland. Reconstructed by Craig Sitch.

Both illustrations above from 'Viking Knives from the island of Gotland

Sweden' by Dan Carlsson (ArkeoDock, 2003)

Everything about the physical structure of the majority of knives from the Viking Age indicates a perception of knife as tool - not knife as weapon. The primary reason to equip an knife with a guard is to protect the hand during fighting. As the artifacts prove, the standard Norse knife is not equipped with a guard. The most common pouch scabbard is designed to be protective and secure - but the style makes it extremely difficult to draw the blade with any speed. The majority of samples are also small, a size that well suits a working tool rather than a combat weapon.

The images shown have been scanned from the texts credited. Note that these images are being used without permission. I strongly recommend that anyone wanting a fuller understanding of this topic simply PURCHASE the volumes indicated.

'Viking Knives from the island of Gotland Sweden' by Dan Carlsson (ArkeoDock, 2003)

Anglo-Scandinavian Ironwork from Coppergate by Patrick Ottaway (York Archaeological Trust, 1992)