15 Oct 2011 - More temperature records

The

goal of this day was to get some additional temperature measurements for different

designs of furnaces for a paper we are working on.

The outcome of this series was the paper:

Glass on Fire: Temperatures in reconstructed Viking Era bead furnaces, in

"Can These Bones Come to Life?" Insights from Reconstruction,

Reenactment, and Re-creation Vol II. It is available from

Freelance Academic Press.

We ran three furnaces this time - the "Sarah", the "Goderich", and the "Neil".

| Furnace Name | Archaeology | Description | Notes |

|---|

| Neil | Ribe Circular design | A "teapot" design.

Single chimney, with annealing pot attached to one side. A single

working port cut into the body. Charcoal is loaded through the working

port or chimney. Walls are standard thickness (3cm) and have a very

pronounced curve joining walls and floor in a bowl shape to aid in

charcoal concentration. The working port is cut high on the wall. | |

| Sarah | Ribe Oval | A smaller version of the

standard shape built with a single chimney. This had originally been

intended to work as a single working port but the plan was changed. A

port was cut into each end, and a diverter added to the inside. The air

port was cut in the usual location. | |

| Goderich | Ribe Oval | Dual chimney oval furnace, cobb construction. Internal

construction includes gentle slopes from walls to floor, and a large air diverter opposite the air port.

There is no opening cut for charging - charcoal is added through the chimneys. Working ports are cut into

each end. Right port uses cuts angled up into the furnace. Left port cuts angle down into the furnace.

Right port produces more heat onto the bead maker. | Good functional furnace with 10 hours of burn

time. |

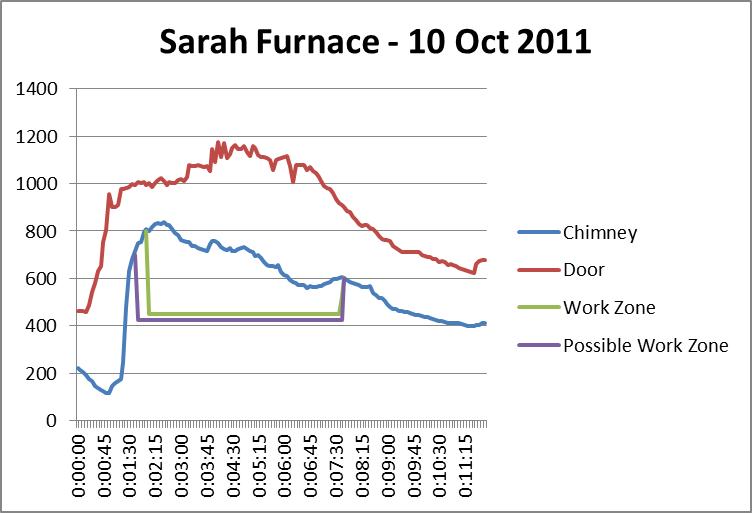

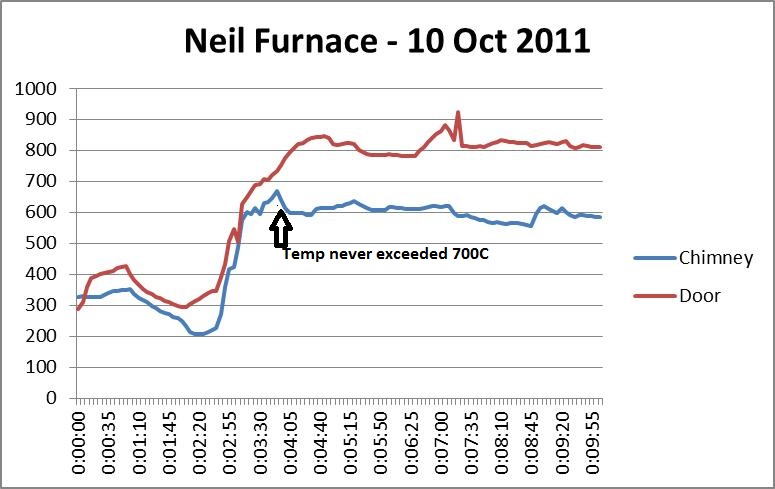

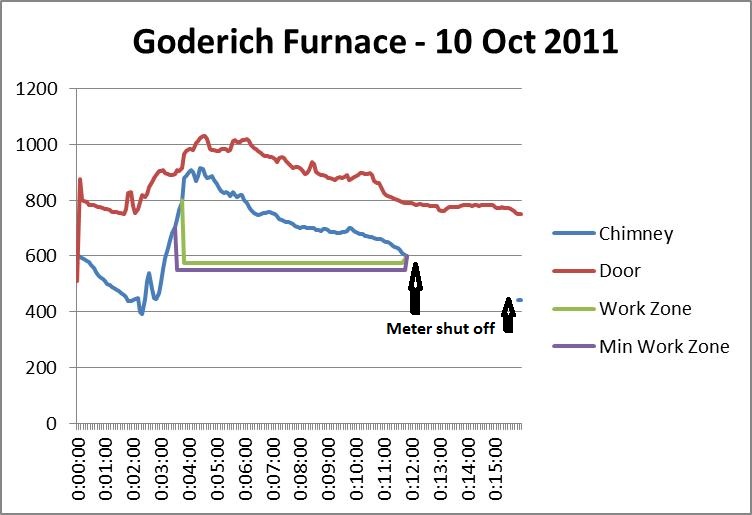

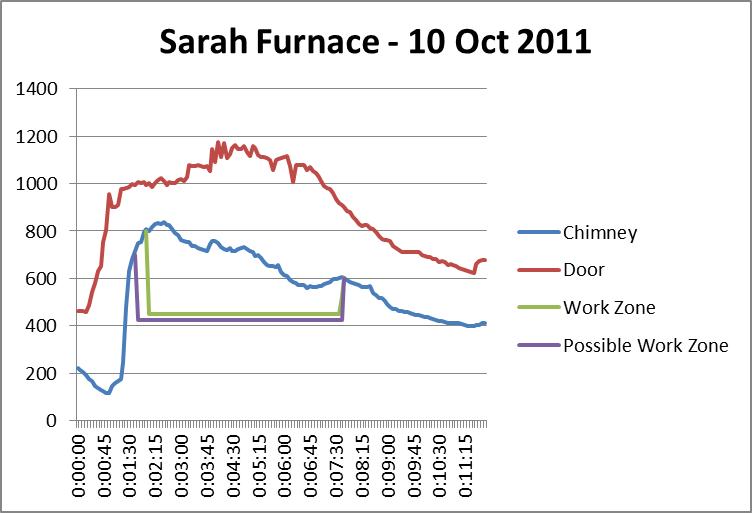

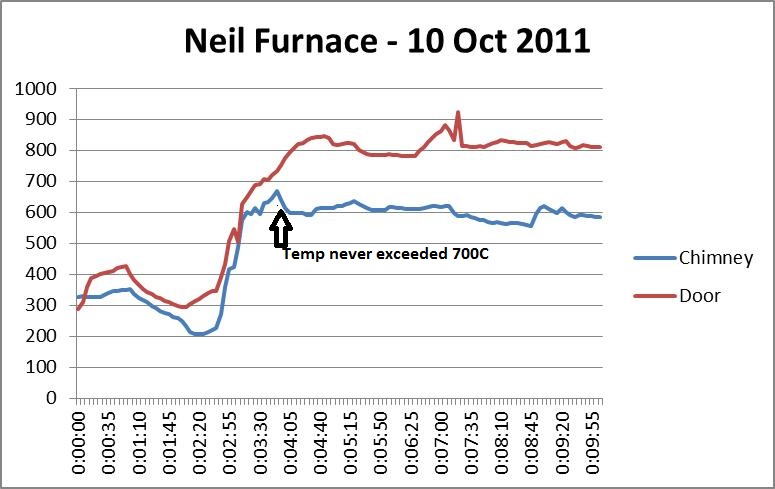

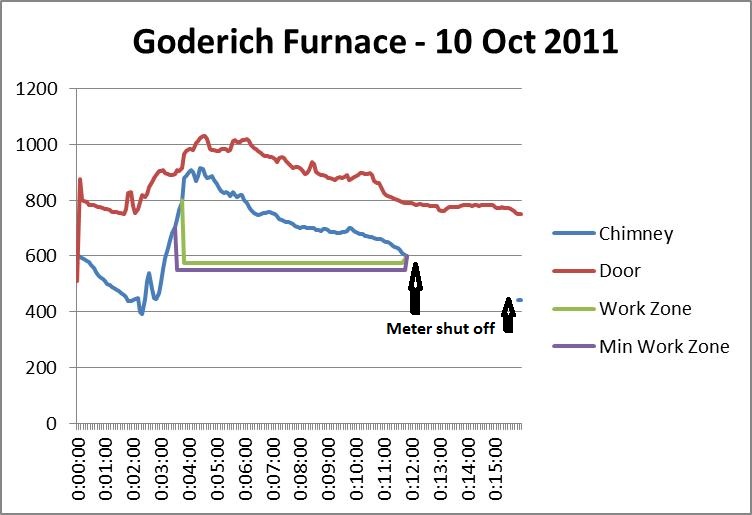

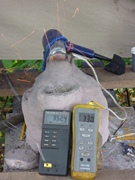

Several videos were made to allow us to plot temperature over time, both in the chimney and in the door.

These are the results.

Operating temperatures

All temperatures are in celcius.

Compressed video (8x normal speed) to go with the chart below

Compressed video

Compressed video (8x normal speed) to go with the chart below

We also got a chance to run and record the "goderich" furnace the next weekend

Compressed video (8x normal speed) to go with the chart below

Videos

Videos

We also have a few videos available:

Photos

|

|

|

|

| The "Neil" furnace |

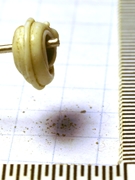

Winding on glass |

Working a bead in the chimney |

Working a bead in the chimney |

|

|

|

|

| Temperature of "Neil" furnace |

The "Sarah" furnace |

Working in the door |

Reticella |

|

|

|

|

| Pulling reticella |

Adding more glass |

Rolling a bead |

Touchng up an edge |

|

|

| |

| Adding reticella |

Sarah getting ready |

Beads Produced

|

|

|

|

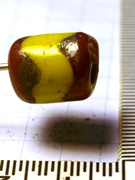

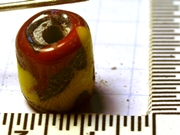

| Black - impacted by atmosphere |

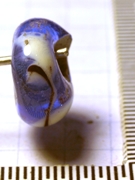

Blue decorated |

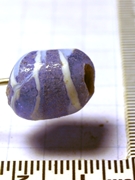

Blue with reticella |

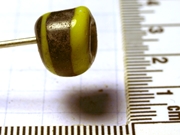

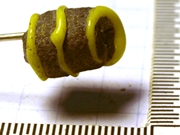

Wasp bead |

|

|

|

|

| Wasp bead 2 |

Wasp bead 3 |

Rayed eye bead |

Dotted |

|

|

|

|

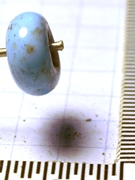

| Light blue |

Clear |

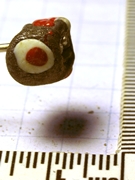

Black with ringed eye |

Second view of bead |

|

|

|

|

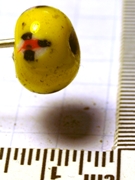

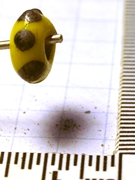

| Yellow with dots |

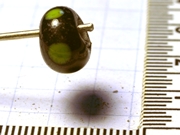

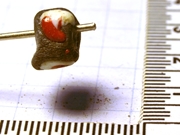

Bead with reticella |

Second view |

Black with red and yellow bands |

|

|

|

|

| Second view |

White |

Two temps |

Furnaces

Following this session the bead furnaces were broken down in order to record more information

about their construction.

Neil

| Exterior diameter of base | 22.5 cm |

| Thickness of base | 18 mm |

| Interior bowl width | 13 cm |

| Depth of bowl (to bottom of door) | 11 cm |

| Bottom of tuyure to bottom of bowl | 5 cm |

| Bottom of bowl to top of chimney | 22.5 cm |

| Measurement | Total (mm) | Sintered (mm) | Dark Clay (mm) |

|---|

| Wall at base of bowl | 70.58 | 4.55 | 16 |

| Wall half way to door | 34.91 | 4.33 | 5.5 |

| Wall at door | 31.33 | 7.24 | 13.18 |

| Wall at top of door | 25.01 | 8.72 | 9.08 |

| Wall at top of chimney | 13.29 | 6.27 | 5.4 |

The floor had only a thin amount of sintered clay, most of it was just blackened. At the center

of the bowl the black was the full thickness while at the edges there was unblackened clay at the

bottom.

On the inside of the bowl the bottom is partially blackened and partially unblackened. The black area is on

the side of the bowl closest to the door and covers a part of the interior wall.

|

|

|

|

| Top view |

Side view |

Air inlet |

Opened between door and tuyure |

|

|

| |

| Wall above door |

Side view of cross-section |

Sarah

| Exterior length | 40 cm |

| Interior length | 32 cm |

| Exterior width | 21 cm |

| Interior width | 14 cm |

| Interior tuyure to diverter | 8.5 cm |

| Exterior height | 25 cm |

| Interior height (to bottom of chimney) | 20 cm |

| Thickness of base | 18 mm |

| Interior bowl width | 13 cm |

| Depth of bowl (to bottom of door) | 11 cm |

| Bottom of tuyure to bottom of bowl | 5 cm |

| Bottom of bowl to top of chimney | 22.5 cm |

| Measurement | Total (mm) | Sintered (mm) | Dark Clay (mm) |

|---|

| Chimney | 17 | 8.2 | 6 |

| Chimney 2nd location | 16 | 7.7 | 7.4 |

| Chimney 3rd location | 16.2 | 6.2 | 5.2 |

| Top shoulder at chimney | 22.5 | 9.2 | 8.2 |

| Top shoulder at chimney 2nd location | 24.8 | 11.9 | 11.9 |

| Above Tuyure | 36.5 | 17.7 | 12.8 |

| Above Door | 32.5 | 19.3 | 11.1 |

| Wall under tuyure | 35 | 13 | 19 |

| Wall under tuyure at base | 50 | 4.5 | 38.7 |

| Base | 23.4 | 4.7 | 7.3 |

|

|

|

|

| Back view |

End view |

Wall below tuyure |

Side view, wall below tuyure |

|

|

|

|

| End view with door |

Base |

Floor |

Goderich

| Exterior width of base | 25 cm |

| Exterior length of base | 54 cm |

| Thickness of base | 18 mm |

| Interior bowl width | 13 cm |

| Base to bottom of door | 2.6 cm |

| Door height | 6.2 cm |

| Base to top of chimney | 28 cm |

| Measurement | Total (mm) | Sintered (mm) | Dark Clay (mm) |

|---|

| Tuyure wall at base | 54.5 | 0 | 12.52 |

| Tuyure wall 1" up | 37.18 | 7.29 | 10 |

| Tuyure wall 2" up | 34.97 | 11.48 | 14.38 |

| Tuyure wall 3" up | 34.68 | 15.9 | 13.17 |

| Tuyure wall 4" up | 30.29 | 13.05 | 14.25 |

| Tuyure wall 5" up | 31.75 | 11.25 | 10.88 |

| Tuyure wall 6" up | 23.59 | 7.95 | 8.69 |

| Tuyure wall 7" up | 19.23 | 11.51 | 7.2 |

| Tuyure wall 8" up | 21.85 | 10.34 | 0 |

| Tuyure wall 9" up | 20.32 | 8.58 | 0 |

| Tuyure wall 10" up | 15.7 | 6.91 | 0 |

| Tuyure wall at top of chimney | 15.8 | 5.44 | 0 |

| Back wall at base | 40.68 | 8.24 | 22.61 |

| Back wall 1" up | 32.86 | 11.91 | 14.44 |

| Back wall 2" up | 35.27 | 10.34 | 19 |

| Back wall 3" up | 32.95 | 14.27 | 9.73 |

| Back wall 4" up | 29.55 | 13.11 | 8.25 |

| Back wall 5" up | 24.05 | 11.06 | 5.09 |

| Back wall 6" up | 21.83 | 12.62 | 6.01 |

| Back wall 7" up | 16.95 | 8.62 | 4.13 |

| Back wall 8" up | 17.75 | 6.68 | 5.66 |

| Back wall 9" up | 20.72 | 8.12 | 5.79 |

| Back wall 10" up | 19.24 | 9.11 | 6.32 |

| Side wall above door | 28.73 | 15.51 | 9.67 |

| Base a door | 52.78 | 18.91 | 25.07 |

| Base 7cm in from door | 25 | 5.82 | All |

The inside of the base showed almost no blackening. Just a small amount at the midpoint between the

door and tuyure.

Underneath the base (exterior) heat blackening was visible in a fairly regular oval starting about 3cm

from the edge. There was no visible difference in the heat marking where the air diverter is

found.

|

|

|

|

| End view |

Back view |

Top view |

Air diverter |

|

|

|

|

| Door to back wall |

Interior |

Underside of base |

Base cross-section |

|

| | |

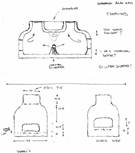

| Plan drawings |

Dark Ages Re-Creation Company

Dark Ages Re-Creation Company