2008 - Directions for AIR

This is a shortened version of an ongoing series of posts over on the Hammered out Bits Blog:

The core members of the DARC smelt team (Neil, Kevin, Dave and Ken) were up over the past weekend. We discussed what we are learning, what we have done, and what direction this year's campaign at the smelter should take.

The main thrust will be work towards the reconstruction of the Icelandic grass sod smelter. At present we have two pieces of technical work to refine. The first (not dealt with there) is the creation of a workable bog ore analog. The second is to finally get an effective bellows design.

2008 year experiments

'Test Bed' Double / Twin bellows for iron smelting

1) Neil has ordered a copy of the small blacksmith's bellows for his glass bead furnace project. This will be made up using the current physical measurements, but with two important changes.

- First the bag will be cut with only two leather lames - giving a maximum loft in use of 30 cm. This will reduce the folding of what is just unused leather surface. The wooden frame will be made up, and then a fast test bag will be made up out of taped plastic. This should allow for a fast test series to be made to measure the air volume with the shorter bag.

- If this test proves effective, then the bags will be made up using a lighter (likely deer skin) leather than has been used on previous versions.

- The centre seam will be fitted with a more rigid metal hoop than has been used in the past (at least 3/16, if not 1/4 inch round steel rod).

Taken together, this new unit should allow us to record more accurate numbers for the possible use of the historic patterned bellows in smelting.

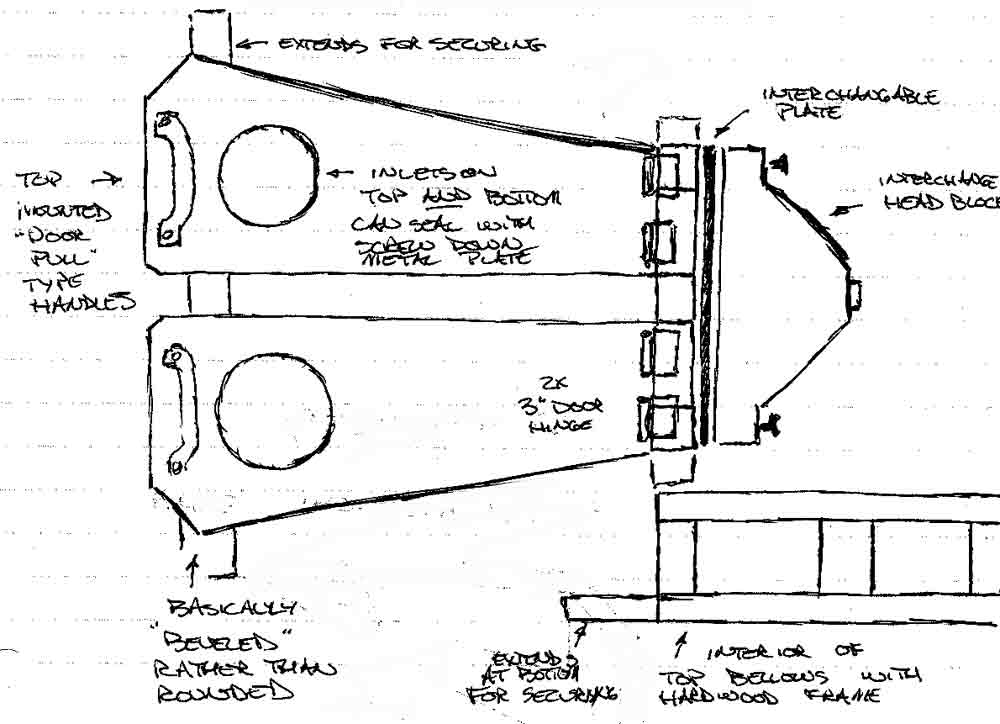

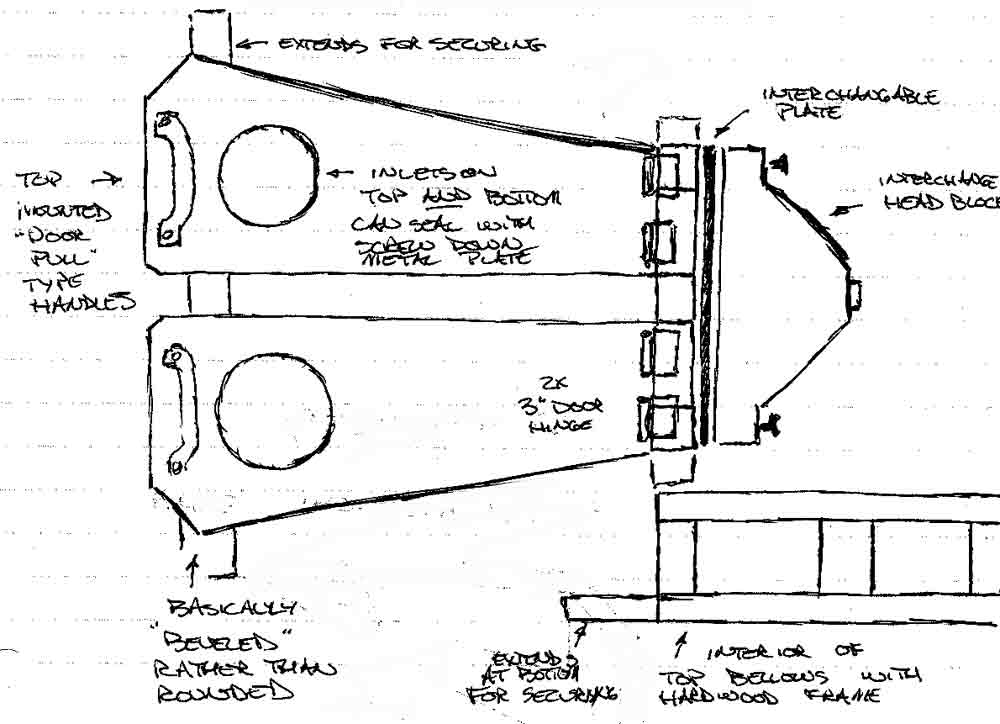

2) A second 'test bed' bellows will be made up (as seen in the illustration above).

- Measurements for this bellows will be determined by taking a theoretical model which is able to produce roughly 1500 LpM. The desired working air volume is actually 1000 LpM. Numbers and images from Jens suggests a true working efficiency of about 2/3 theoretical is likely (assuming good design). Working from more theoretical and experience proven volume requirements, our current run of furnaces work best at roughly 500 to 800 LpM.

- The sides of the bellows will be flat surfaces. This allows us to hold the bags in place with metal strips held with screws. This permits easy modifications to the interior of the bag and plates if required.

- The bellows plates will be cut and fitted with intake holes on both top and bottom. In use, either side can be sealed using a metal cover again screwed into place. In this way the difference between top and bottom mounted air valves can be compared. Physical mounting systems for the bellows, and how this relates to operator strain can be compared. An extension of this is further recording of the related debris fields.

- The distance at hinge point of the bellows will be greatly increased, at least double the current measurement. This will allow the installation of two door type hinges on each plate, greatly improving durability.

- The head block of the bellows is a simple boxed shape. To this can be screwed a removable, even interchangeable, exhaust unit. Different types of valves, port shapes and tube diameters can then be attached to measure their impact on flow.

- The handle for the operator will be a wide wooden D type. This will be mounted directly in line with the bellows hinge axis.

Most of the tests involved are primarily static tests, or short applications of human power to the existing air pipe system. There was more interest than I expected in conducting a full smelt using a proven bellows for air. With a proven smelt (bloom production) DARC will have a certain 'all Norse' demonstration possible.

Darrell

The core members of the DARC smelt team (Neil, Kevin, Dave and Ken) were up over the past weekend. We discussed what we are learning, what we have done, and what direction this year's campaign at the smelter should take.

The main thrust will be work towards the reconstruction of the Icelandic grass sod smelter. At present we have two pieces of technical work to refine. The first (not dealt with there) is the creation of a workable bog ore analog. The second is to finally get an effective bellows design.

1) Neil has ordered a copy of the small blacksmith's bellows for his glass bead furnace project. This will be made up using the current physical measurements, but with two important changes.

- First the bag will be cut with only two leather lames - giving a maximum loft in use of 30 cm. This will reduce the folding of what is just unused leather surface. The wooden frame will be made up, and then a fast test bag will be made up out of taped plastic. This should allow for a fast test series to be made to measure the air volume with the shorter bag.

- If this test proves effective, then the bags will be made up using a lighter (likely deer skin) leather than has been used on previous versions.

- The centre seam will be fitted with a more rigid metal hoop than has been used in the past (at least 3/16, if not 1/4 inch round steel rod).

Taken together, this new unit should allow us to record more accurate numbers for the possible use of the historic patterned bellows in smelting.

2) A second 'test bed' bellows will be made up (as seen in the illustration above).

- Measurements for this bellows will be determined by taking a theoretical model which is able to produce roughly 1500 LpM. The desired working air volume is actually 1000 LpM. Numbers and images from Jens suggests a true working efficiency of about 2/3 theoretical is likely (assuming good design). Working from more theoretical and experience proven volume requirements, our current run of furnaces work best at roughly 500 to 800 LpM.

- The sides of the bellows will be flat surfaces. This allows us to hold the bags in place with metal strips held with screws. This permits easy modifications to the interior of the bag and plates if required.

- The bellows plates will be cut and fitted with intake holes on both top and bottom. In use, either side can be sealed using a metal cover again screwed into place. In this way the difference between top and bottom mounted air valves can be compared. Physical mounting systems for the bellows, and how this relates to operator strain can be compared. An extension of this is further recording of the related debris fields.

- The distance at hinge point of the bellows will be greatly increased, at least double the current measurement. This will allow the installation of two door type hinges on each plate, greatly improving durability.

- The head block of the bellows is a simple boxed shape. To this can be screwed a removable, even interchangeable, exhaust unit. Different types of valves, port shapes and tube diameters can then be attached to measure their impact on flow.

- The handle for the operator will be a wide wooden D type. This will be mounted directly in line with the bellows hinge axis.

Most of the tests involved are primarily static tests, or short applications of human power to the existing air pipe system. There was more interest than I expected in conducting a full smelt using a proven bellows for air. With a proven smelt (bloom production) DARC will have a certain 'all Norse' demonstration possible.

Darrell

Labels: blacksmithing, iron smelting